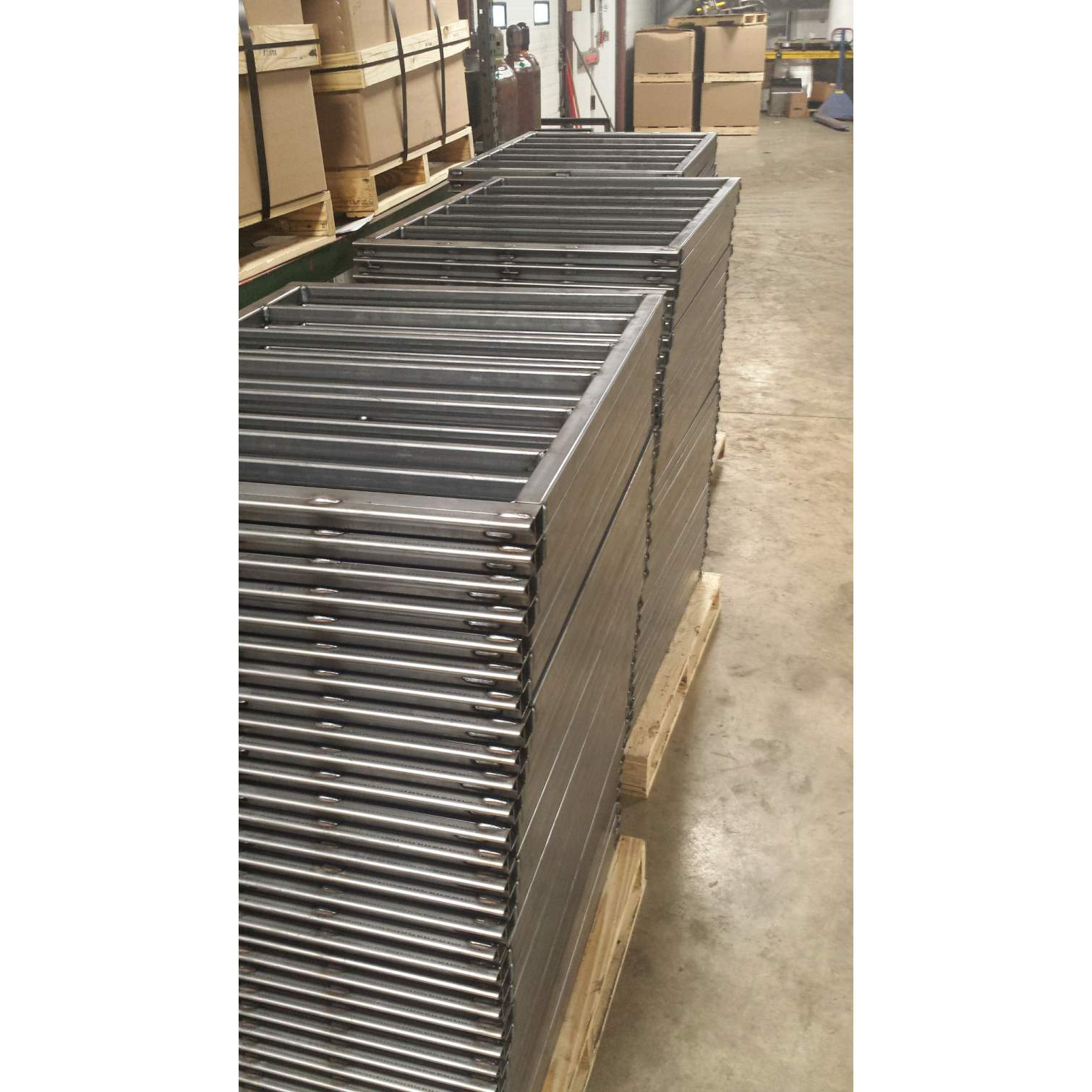

Bear Metal Works’ first ever customer is an Oil and Gas Manufacturer that provides vibrating and filter machines all over the globe. Bear Metal Works’ two robotic welders provide hundred of welded carbon steel tube frames weekly for this customer. These frames are completely welded together, ground flush and sent out to get apoxy-coated green. These frames get a filter screen glued on top of them and put into the vibrating shaker machines to filter out rocks/dirt from oil refineries.

Another product Bear Metal Works provides for this customer are Ratchet Jacks that go on these shaker machines and used in the field. These jacks are made up to specific customer drawings that include multiple parts. Acme threaded rod, gears, and round tubing make up these jacks that get a zinc plating put on them before being shipped out for customer use.